OUR PRODUCTS

Our Product Range

Steel Blades Are Commonly Shaped By Forging Or Stock Removal. Forged Blades Are Made By Heating A Single Piece Of Steel, Then Shaping The Metal While Hot Using A Hammer Or Press. Stock Removal Blades Are Shaped By Grinding And Removing Metal. With Both Methods, After Shaping, The Steel Must Be Heat Treated.

Knives Are Sharpened In Various Ways. Flat Ground Blades Have A Profile That Tapers From The Thick Spine To The Sharp Edge In A Straight Or Convex Line. Seen In Cross Section, The Blade Would Form A Long, Thin Triangle, Or Where The Taper Does Not Extend To The Back Of The Blade, A Long Thin Rectangle With One Peaked Side

Slitting Line Tooling

ALTAR KNIVES can manufacture Slitting Line tooling up to 500mm diameter.

Wood peeling knives

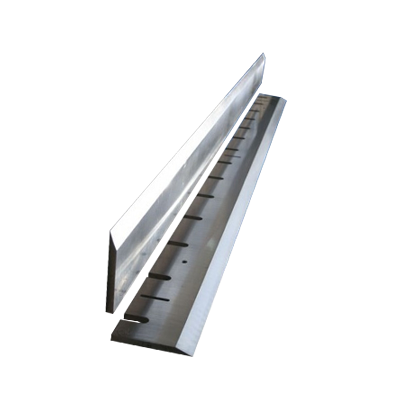

Shear Blades / Shear Knives / Chipper Knives

ALTAR KNIVES produces various straight cutting blades. Our range of products: cutting blades for wood industries, plastic industries, metal industries